First, industrial automation definition

Industrial automation refers to the application of automation technology in the machinery industry manufacturing link, to achieve automatic processing and continuous production, improve the efficiency and quality of mechanical production, and release productivity means of operation. The development of industrial automation relies on the deep integration of information technology, computer technology and communication technology, and automation technology has reversed the traditional operation mode to a large extent and accelerated the transformation of traditional industrial technology.

Industrial automation technology is now widely used in the production, control and management of industrial enterprises, which effectively improves the daily operation efficiency of industrial enterprises and the scientific nature of industrial production.

Second, industrial automation main products

Industrial automation products can be divided into control systems, drive systems, executive systems and feedback systems and output systems. The control system includes PLC, CNC system, IPC/ MCU, DCS, HMI and industrial software, etc. The drive system includes servo drive, frequency converter, soft starter, DC drive and industrial converter. The execution system includes servo motor, AC motor, reducer, contactor and regulating valve, etc., while the feedback system includes sensors, process instruments and testing instruments. The output system includes robots, CNC machine tools, auxiliary machinery and non-standard equipment.

1. The scale of industrial automation industry continues to grow rapidly

China's industrial automation industry started late, but the development momentum is strong. Although there is a significant gap between China's industrial automation and foreign brands in the key core technologies, a series of regulations and policies promulgated by the state in recent years have provided a strong driving force for the development of China's industrial automation industry. China's industrial automation industry has made significant progress, and the domestic substitution process has accelerated. Data show that in 2023, China's industrial automation market size reached 311.5 billion yuan, an increase of about 11% compared with 2022. China Business Industry Research Institute analysts predict that the size of China's industrial automation market will increase to 353.1 billion yuan in 2024

Data source: China Business Industry Research Institute

In the future, with the continuous advancement of the global industry 4.0 era, the demand for industrial automation equipment in various application fields will further increase, and China Business Industry Research Institute analysts predict that the global industrial automation market will reach 509.59 billion US dollars in 2024.

Source: Frost&Sullivan

2. Production of industrial automation core products

The core products of industrial automation are industrial robots and CNC machine tools. In terms of the industrial chain, industrial robots are the main components of industrial automation. Industrial robots are considered to be "easy-to-use numerical control machines that require more motion control." Compared with CNC machine tools, industrial robots are more versatile, more powerful, easier to operate and maintain. In addition, industrial robots have a broader downstream integration space, and there is significant room for future growth. By the end of 2023, the annual output of industrial robots in China exceeded 400,000 units, and the overall value is expected to reach 66.588 billion yuan in 2023, and the market size of CNC machine tools is expected to reach 409 billion yuan in the same period. China Business Industry Research Institute analysts predict that in 2024, China's industrial robot market will increase to 72.642 billion yuan, and the market size of CNC metal machine tool industry will reach 432.5 billion yuan during the same period.

Source: National Bureau of Statistics

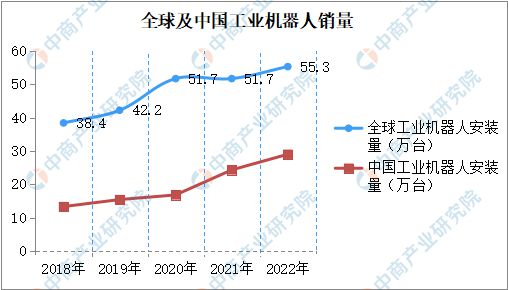

3. Sales of industrial automation core products

The "2023 World Robot Report" released by the International Federation of Robotics (IFR) shows that the number of new industrial robots installed in global factories in 2022 is 553,052, an increase of 5%. Asia accounted for 73%, Europe 15% and the Americas 10%.

As the world's largest market for industrial robots, China installed 290,258 units in 2022, an increase of 5% year-on-year, setting a new record for 2021. Since 2017, robot installations have grown at an average annual rate of 13%.以上翻译结果来自有道神经网络翻译(YNMT)· 通用场景

逐句对照

AI润色

Data source: Public data collation

Fourth, industrial automation development prospects

1. The scale of the downstream market of industrial automation continues to grow, and the development of the industrial automation industry is reversed

With the continuous maturity of industrial automation technology, the application scale of industrial automation equipment such as production devices, control devices, feedback devices and auxiliary devices in machine tools, wind power, textiles, packaging, plastics, construction, mining, transportation and medical industries continues to expand, making the industrial automation market has been greatly developed.

2. Intelligent, high precision and high reliability bring high-end product demand

With the development of information technology and manufacturing technology, the industrial system of intelligent manufacturing equipment such as new sensors, intelligent control systems, industrial robots, and automated complete production lines has initially taken shape, and automation equipment has put forward higher requirements for the intelligence, accuracy and reliability of its transmission and braking systems. With the development of equipment to intelligence and automation, changes in downstream application requirements will bring more market space for the industrial automation industry.

3. Rapid increase in localization rate

With the transfer of global manufacturing to China in recent years, Chinese enterprises in the industrial automation industry have obtained advanced technology and manufacturing experience, and the overall industry has developed rapidly, but because China's core technology and high-end products are still highly dependent on foreign countries, domestic enterprises still have a big gap with their competitors in developed countries. Domestic enterprises are mainly concentrated in the field of traditional equipment. Such as construction machinery, heavy machinery, silicone equipment, power tools, etc., the products are mainly low-end basic products, and industrial robots, CNC machine tools, semiconductor equipment and other automation equipment field is still occupied by foreign enterprises occupy a larger market share. With the continuous enhancement of technological research and development strength of Chinese enterprises and the continuous improvement of product performance, more and more high-quality enterprises will participate in the competition in the high-end product market, and the import substitution potential is huge.

Note: The above content (if there are pictures or videos also included) is uploaded and published by users of the self-media platform "NetEase", if there is infringement, please contact to delete